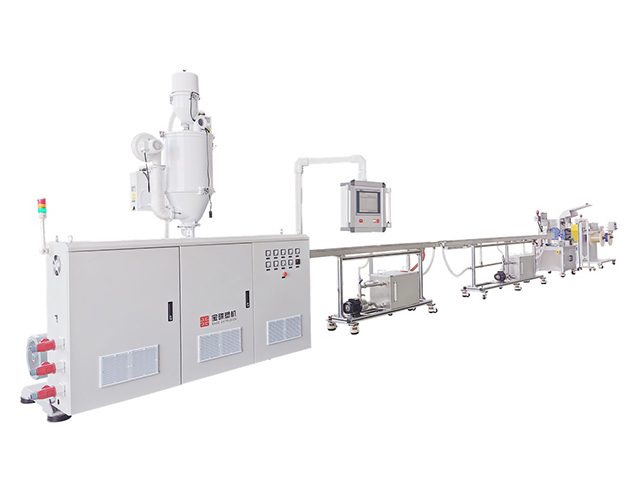

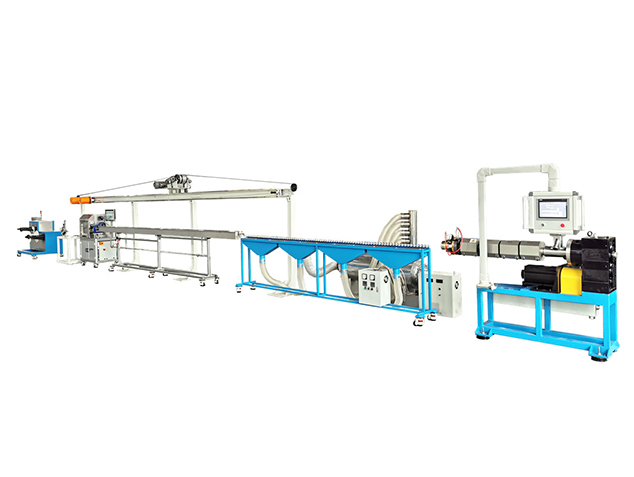

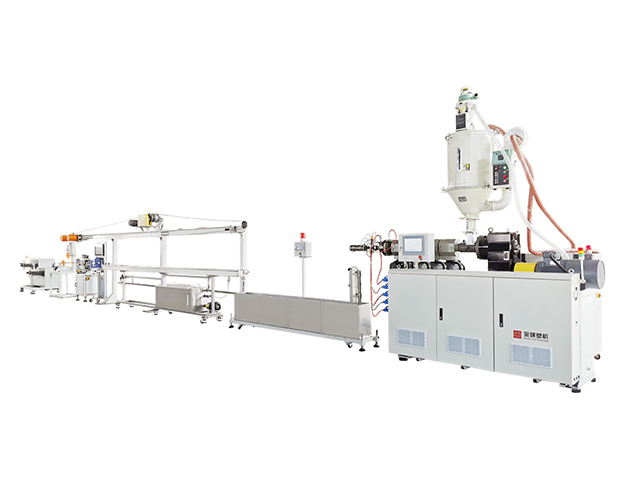

Layin Filament Filament na 3D (Nau'in Daidaitawa)

-

Gudun samarwa:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Sarrafa daidaito:

Φ3.0 mm zuwa 2.9 mm, 1.70 zuwa 1.80 mm. (Max ≤± 0.04mm, Matsakaici≤± 0.03mm, CPK≥1.6).

Bayanin samfur

Siffar filament na firinta na 3D suna da ƙarfi zagaye waya a halin yanzu, babban albarkatun ƙasa yana da PLA, PVA, HIPS, ABS, PC, PA, TPU da dai sauransu, samfuran kewayo daga 1.75 mm zuwa diamita 3.0 mm. BAOD EXTRUSION bayar da na farko sa 3D PRINTER FILAMENT extrusion inji ga abokan ciniki a 2009, bayan dogon lokaci ci gaba da inganta kayan aiki sanyi da kuma extrusion fasahar, mun kafa wani sa na cikakken na musamman ga 3D bugu consumables extrusion line, wasa tare da goyon bayan daban-daban dunƙule da kuma mutu gyare-gyaren fasaha, iya gamsar da daban-daban irin kayan' samar.

Muamfani

Siffofin Layin Inji

1. Cikakken SERVO drivingis sanye take akan layin injin gabaɗaya, yana kaiwa ga babban barga yana gudana ga kowane sassa akan layin extrusion, kamar narke extruding, narke metering, ja, da sauransu;

2. Sanye take da metering famfo tsarin, redouble tabbatar da daidaito na narke kwarara, a halin yanzu ƙara mutu shugaban matsa lamba don kauce wa m ciki na waya;

3. An sanye shi tare da ma'aunin laser diamita na kan layi da aikin sarrafa ra'ayi na diamita ta atomatik, sarrafa juzu'in juzu'i zuwa ƙaramin ƙima, haɓaka matakin gabaɗayan aikin sarrafa layi;

4. Winding da traversing ta hanyar SERVO drive & PLC sarrafa shirye-shiryen don gane daidaitaccen layi da tsari (mai kyau) iska, iskar da ke samuwa ga manya da ƙananan spool.