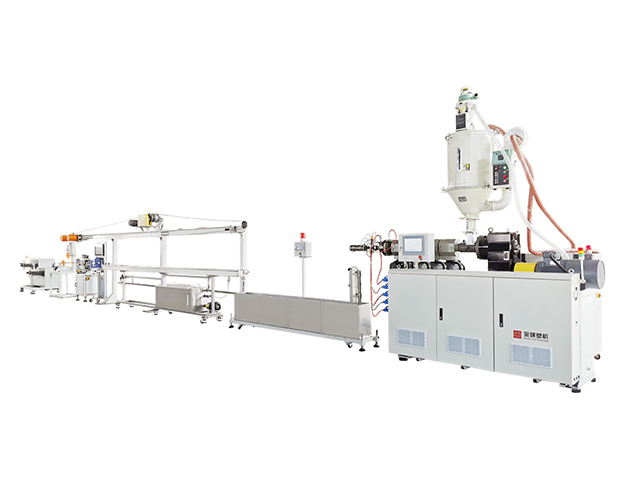

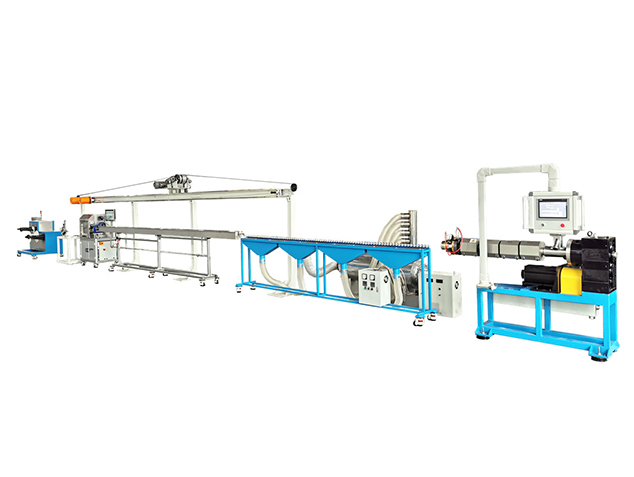

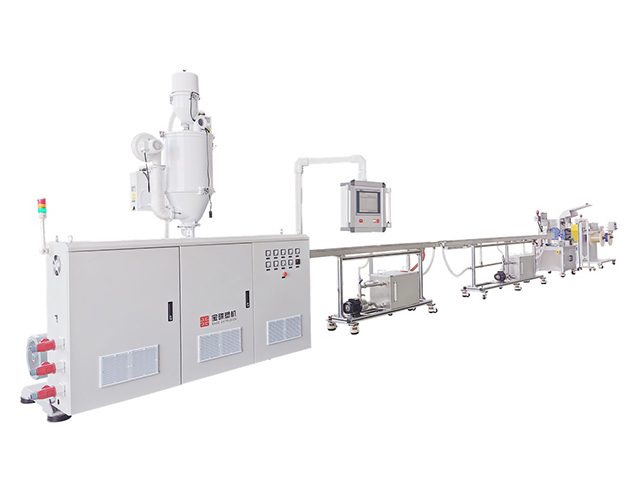

Layin Extrusion Filament na Fitar 3D (Tsaye Tsaye)

-

Gudun samarwa:

DN1.75mm 120-150m/min, DN3.0mm 45-55m/min.

-

Sarrafa daidaito:

Φ3.0 mm zuwa 2.9 mm, 1.70 zuwa 1.80 mm. (Max +/-0.04mm, Matsakaici +/-0.03mm, CPK≥1.6)

Bayanin samfur

Siffar filament na firinta na 3D suna da ƙarfi zagaye waya a halin yanzu, babban albarkatun ƙasa yana da PLA, PVA, HIPS, ABS, PC, PA, TPU da dai sauransu, samfuran kewayo daga 1.75 mm zuwa diamita 3.0 mm. BAOD EXTRUSION ya ba da saitin farko na 3D PRINTER FILAMENT extrusion na'ura ga abokin ciniki a cikin 2009. Bayan dogon lokaci na gwaji da tabbatarwa, mun gano cewa don babban narke ya kwarara kudi polymer kayan (kamar TPU, PA, PC, da dai sauransu) ta tsaye. sanyaya calibration tsari, da kafa size (musamman da elliptical) na filament da aka muhimmanci inganta. A adaptability na 3D firintar filament extrusion aiwatar da kayan da aka kara fadada.

Muamfani

Siffofin Layin Inji

1. Cikakken servo tuki sanye take a kan dukan inji line, kai ga high barga Gudun ga kowane sassa a kan extrusion line, kamar narke extruding, narkewa metering, ja, da dai sauransu.;

2. An sanye shi da tsarin famfo mai ƙididdigewa, sau biyu tabbatar da daidaiton kwararar narke, yayin da yake ƙara matsa lamba mai mutuƙar mutuƙar don guje wa faɗuwar cikin waya;

3. An sanye shi tare da ma'aunin laser diamita na kan layi da aikin sarrafa ra'ayi na diamita ta atomatik, sarrafa juzu'in juzu'i zuwa ƙaramin ƙima, haɓaka matakin gabaɗayan aikin sarrafa layi;

4. Winding da Traversing ta hanyar SERVO drive & PLC sarrafa shirin don gane daidaitaccen layi da tsari (mai kyau) iska, iskar da ke samuwa ga manya da ƙananan spool.