Bayanin Samfura

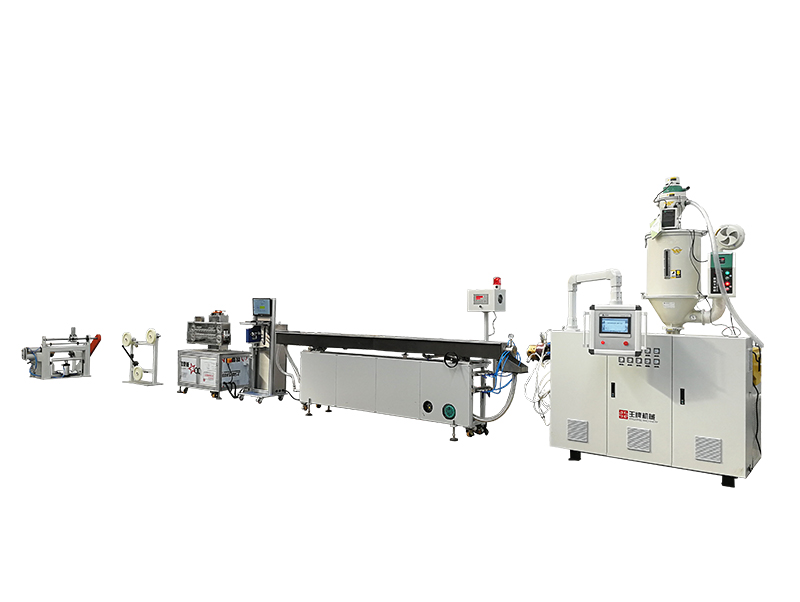

Dangane da ɗimbin ƙwarewar aiki da fasahar Jafananci, mun haɓaka layin na uku na PA daidaitaccen bututun extrusion, wanda abokan cinikinmu suka karɓe sosai daga gida da waje.

Ƙarshen masu amfani da mu: Ƙungiyar CHINAUST, Sanoh Industrial, Arkema, HUATE Group, da dai sauransu.

Muamfani

Siffofin Kayan aiki

- PA (nailan) dunƙule ne DSBM-T MADDOCK Barrier nau'in hadawa na'ura mai ba da hanya tsakanin hanyoyin sadarwa wanda zai iya daidaita daidai da kayan PA wanda yake tare da babban zafin thermal, mai gudana da narkewar danko, don haka tabbatar da ingantaccen filastik da ingantaccen fitarwa;

- Core sanduna da mutu an yi Sweden "ASSAB" S136 mutu karfe, daidaici nika, wanda tabbatar da ciki ya kwarara surface glossiness da anti-lalata. Tsarin mold rungumi dabi'ar "high matsa lamba volumetric nau'in", wanda aka qaddamar da mu kamfanin, na iya samar da barga da high-gudun extrusion ga bututu abu tare da kankanin hawan jini;

- Tare da sabon fasaha na "daidaitaccen iko ta atomatik na vacuum": injin ruwa da tsarin ruwa ana sarrafa su daban. Ta wannan hanyar, za mu iya daidaita tsarin kula da ma'auni na ruwa da yawa tare da tsarin injin, tabbatar da kwanciyar hankali matakin injin, sanyaya matakin ruwa da kwararar ruwa.

- Babban aikin aunawar Laser, samar da tsarin kulawar madauki mai rufewa, kawar da karkatar da diamita akan layi;

- Puller sanye take da bel mai juriya mai juriya da yawa, ba tare da zamewar al'amari ba. Babban matakin madaidaicin abin nadi, tsarin tuki na YASKAWA Servo ko tsarin tuki na ABB AC, gane jajircewar ja.

- Dangane da tsarin tuki na Servo, Japan Mitsubishi PLC mai sarrafa shirye-shiryen sarrafawa da ƙirar kwamfuta ta mutum ta SIEMENS, mai yankewa na iya gane madaidaicin ci gaba da yankewa, yankan lokaci, yankan tsayin kirgawa da sauransu. Za'a iya saita tsayin yanke da yardar kaina, kuma ana iya saita lokutan yanke ta atomatik, wanda zai iya saduwa da buƙatun yanke daban-daban na tsayi daban-daban.

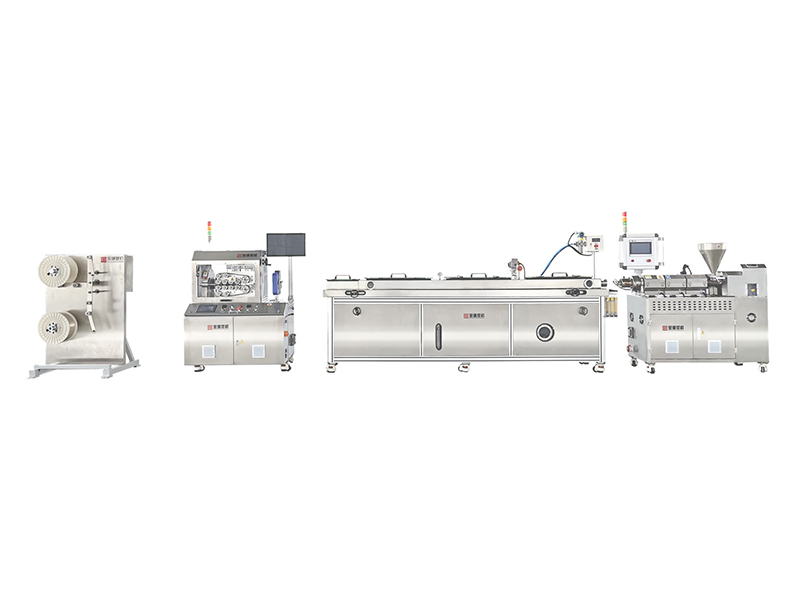

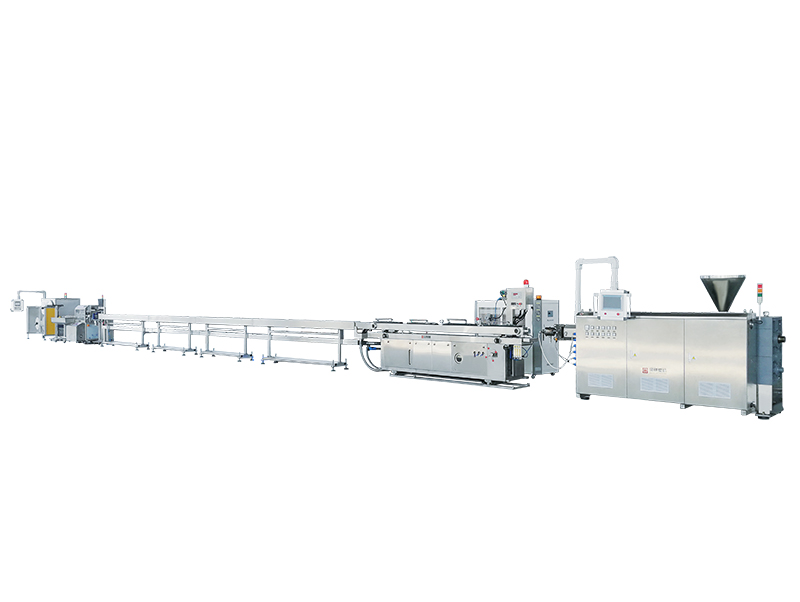

Mutu

Calibration hannun riga

Wurin sanyaya tanki

Laser ma'auni

Mai ja da abin yanka

Tankin tattarawa

Injin iska

Babban Sigar Fasaha

| Samfura | Tsarin diamita na bututu (mm) | Diamita na dunƙule (mm) | L/D | Babban iko (KW) | Fitowa (Kg/h) |

| SXG-45 | 3.0 zuwa 12.0 | 45 | 30 | 15 | 18-30 |

| SXG-50 | 3.0 ~ 16.0 | 50 | 30 | 18.5/22 | 28-45 |

| SXG-65 | 3.0 zuwa 20.0 | 65 | 30 | 37/45 | 55-85 |

| SXG-75 | 3.0 zuwa 20.0 | 75 | 30 | 55/75 | 80-110 |

Ƙayyadaddun Ƙwararrun Tube na PA da Ƙarfafa Matsayin Ƙirƙira

| OD (mm) | Samar da sauri(m/min) | Daidaitaccen sarrafa diamita(≤mm) |

| 4.0 | 80-100 | ± 0.05 |

| 6.0 | 60-80 | ± 0.05 |

| 8.0 | 40-50 | ± 0.08 |

| 10.0 | 25-40 | ± 0.08 |

| 12.0 | 16-30 | ± 0.10 |

| 14.0 | 12-20 | ± 0.10 |

| 16.0 | 10-15 | ± 0.12 |

Yanke Daidaiton Magana

| Tsawon yanke | ≤50mm | ≤500mm | ≤1000mm | ≤2000mm |

| Yanke daidaito | ± 0.5mm | ± 1.0mm | ± 2.0mm | ± 3.0mm |